The purpose of the furniture designer for drilling holes, which is

A device for preparing holes in products is a furniture conductor for drilling holes, which is widely used in the manufacture of various designs. They are made of metal, chipboard, solid wood and other building materials. The conductor, which is the conductor for the drilling tool, can be made independently. The use of this device facilitates the work if you want to make furniture for the home master. He perfectly fulfills his role in assembling furniture consisting of separate blocks.

Appointment

This device is required to direct the drill with high accuracy to a given location, while ensuring the directness and accuracy of its passage through the entire depth of the hole. When working with a hand drill, it is quite difficult to maintain a given direction. If necessary, make a series of holes at a certain distance from each other, you have to make markings for each of them. The furniture template has through holes for the entrance of the drill, the places of which correspond to the product drawing.

In the absence of a conductor, you have to resort to a more time-consuming method - turning the marking lines. A core is a recess on the surface when struck with a hammer on a special cone called a center punch. When installing the jig over a given point, you can start working without pivoting. The drill will hit the desired point accurately and does not deviate from the given direction.

The conductor is used at the assembly stage, hardware fasteners and other technological operations. If you need to make several rows of holes according to the template, the jig significantly saves time. The conductor is almost indispensable when the holes are planned in a rounded shape. The end of the drill, when pressed, jumps off from the place indicated by the drawing. The conductor is fixed on the part and accurately performs the work.

For almost any furniture except wooden, metal structures are used. Often they are pipes through which a series of holes must be drilled. In this case, in the manufacture of the conductor, special attention should be paid to its reliable mounting on a metal pipe. As a rule, the angle during drilling should be 90˚. A rarer and more difficult option is to drill “obliquely”. In this case, adjust the length of the locking elements. Drilling on a tangent is impossible, just holding the drill in your hands. Working with a furniture jig makes this process a snap. You should set the height. In this case, the workpiece is pressed tightly against the stop. The holes are accurate and at the required angle.

The furniture conductor for drilling should be held on the part, no matter how well it is fixed. This is especially worth doing first. Otherwise, there is a likelihood of displacement from vibration.

An essential advantage of using the template conductor for furniture products is that the holes are coaxial. When using a conductor, there is no need to make a calculation and mark out places for holes. This reduces the complexity and reduces the working time.

Even a simple fixture in the form of a strap with an emphasis greatly facilitates and accelerates the process of manufacturing the same holes

Even a simple fixture in the form of a strap with an emphasis greatly facilitates and accelerates the process of manufacturing the same holesVarieties

Existing types of conductors:

- consignment notes - they are mounted on the part for which it was manufactured. If necessary, fix with clamps;

- rotary - they are intended for drilling in cylindrical surfaces. They are equipped with various steering axles. This allows you to work from different angles. On the conductor body there are bushings that specify the direction;

- overturned - if necessary, create several holes in one installation located in different planes;

- sliding - the conductor of this type of fastening does not require. It is applied to the desired surface area. This is possible when there is no need to drill in the exact place. For each hole, the application occurs separately;

- universal - convenient with the ability to readjustment, which is important for small-scale production.

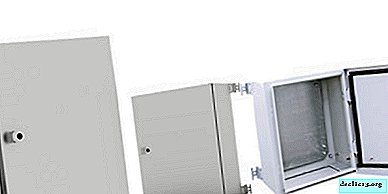

The most commonly used are overhead conductors made of light materials. They are easy to install on the surface in the intended place. Using patch templates, you can drill holes in chipboard parts, MDF boards. One option is an overhead conductor having a turret. The pivoting view is suitable for complicated parts. Universal can be selected for Euroscrews, rafix and so on.

Overhead

Overhead Overturned

Overturned Drilling

Drilling Universal

UniversalApplication rules

Furniture jigs help to avoid the main problem when working - getting the drill into the part at the wrong angle. This error can often cause difficulties in fixing or even send the item to the marriage. The use of the template explorer when drilling holes allows you to correctly orient the tool to a given place and does not allow it to stray from the direction. Holes are made to connect furniture blocks and to fit hardware.

If the hole is not through, then a special emphasis should be put on the drill - a stop. Otherwise, the screw head will begin to fall through the through hole. If we drill at a given angle, then a specific conductor will help to adjust the inclination.

Successful use of jig patterns is possible with a secure fit. The most popular method of attachment is the use of clamps. Such an auxiliary tool is made of metal or wood. Clamps used for fixing conductors for furniture can also be made independently.

Another method of attaching the conductor are spring stops. They press the conductor to the surface of the part due to elasticity. As a stop, a spring having the necessary force can come up. Another way to fix it is to use self-tapping screws. They are screwed into the part, as a result of which the conductor is kept from moving due to friction forces.

How to do it yourself

In the market for construction products, there are a sufficient number of pattern guides for furniture. Among home craftsmen engaged in the manufacture of furniture with their own hands, or working furniture workshops, the most popular are:

- "Assistant" - a device for marking, which has numerous functions;

- "Dubel-Profi" - a conductor, the set of which includes several devices in the form of clamps and rulers, which makes the work more convenient;

- "Condor" - a conductor equipped with positioning capability and having various bushings.

Comfortable and multifunctional are furniture conductors from the manufacturer "Cheron".

Assistant

Assistant Dubel-profi

Dubel-profi Condor

CondorHome craftsmen who are fond of making furniture will probably make a decision on the manufacture of a conductor with their own hands. For them, this will be a familiar job, but faster and easier. For the manufacture of conductors, which are the conductor, you will need a wooden block or a metal sheet. Depending on this, you should prepare tools for work. A conductor need not be made universal. Sometimes it’s easier to make several conductors for the drill, each of which will be used for different purposes.

A simple model can be made from materials available in the house. They can be: fittings, metal plates. This will save your money. The manufacture of the conductor depends on its type. The need for its manufacture may arise when drilling requires non-standard holes.

Before starting the manufacture of the conductor, you should perform its drawing. There are furniture standards that govern the location of holes. When drawing up a drawing, you should adhere to them.

A set of materials and tools are:

- metal sheet or wooden block;

- drill;

- apparatus for welding;

- a set of locksmith tools;

- angle grinder;

- pliers;

- Screwdriver Set;

- bushings;

- sandpaper;

- a grinder or hacksaw for metal;

- fittings;

- welding machine, which is necessary in the manufacture of complicated structures.

With additional requirements, missing parts and equipment can be purchased.

Stages of manufacturing a jig for furniture:

- prepare the blank and clean it;

- cut off pieces of the required length from fittings having a square profile with a cross section of approximately 10 x 10 mm. You can use a hacksaw for metal or grinder;

- the centers of the holes are located at a distance of 8 mm from the edge of the plate. This is specified in furniture manufacturing standards;

- according to these standards, the holes are spaced 32 mm apart. The diameter of these holes is 5 mm;

- the use of the conductor will be more convenient if it is equipped with stops, including swivels. To do this, you will need a metal plate measuring 1x25 mm, which must be bent at an angle of 90 ° and then fixed on the fixture;

- fix with special clamping devices - clamps separate parts of the structure;

- connect the necessary parts using threaded fasteners.

When using furniture conductors, a large amount of dust is generated. So that it does not interfere with the work, the conductor design is supplemented with a small pallet. When drilling, chips and small particles will accumulate there.

The furniture template for drilling holes includes the following parts:

- angular elements of the body, superimposed over the surface of the part. They are connected with the help of dowels, dowels or confirmations;

- guide bushings into which the drilling tool will enter;

- clamps and clamps. They are placed from the end surface of the conductor for the manufacture of furniture.

If you want to make a furniture conductor yourself, the home master should consider what options are most common with him. In order not to invent a new option every time and not spend time and money on it, it makes sense to make a conductor that will be as versatile as possible specifically for its type of activity.

Choosing the parts for the design, you must follow the instructions of regulatory materials. Choosing a corner, it should be noted that according to the assortment GOST 8510, the smallest permissible dimensions are 63 × 40 × 8 mm. If the shelf has a thickness of 8 mm, then a sleeve can be placed on it for the correct direction with a diameter of not more than six mm. The diameter of the hole in the conductor under these conditions should be less than 4 mm. This size is normal.

When designing the sleeve, its dimensions can be taken from GOST 9941 or GOST 9940 for all-welded. It is necessary to choose a pipe according to the diameter of the inner hole. The sleeve length is chosen at least twice the height of the drilled hole. The fit of the sleeve is selected with an interference fit. How many holes there will be and the distance at which they are located depends on the particular product. A good option is to use bushings from the extruder used to pull the wire. The materials of such nozzles are alloy steel, in which the metal “wins” is added. Their service life is almost endless.